Product Description

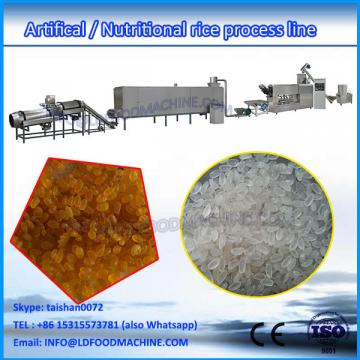

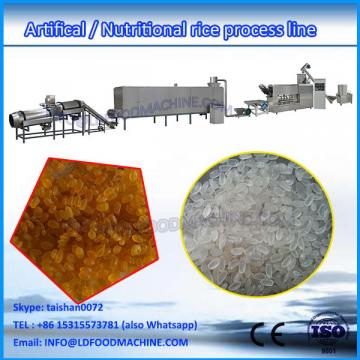

Snack This process line used rice as the main raw material, and some other vitamin and mineral material can be chosen as the products required. The material is extruded into rice shape by the double-screw extruder, and dried to needed moisture content. The extruding technique makes it possible to strengthen the micronutrient in the rice and solidify it.

Snack This process line used rice as the main raw material, and some other vitamin and mineral material can be chosen as the products required. The material is extruded into rice shape by the double-screw extruder, and dried to needed moisture content. The extruding technique makes it possible to strengthen the micronutrient in the rice and solidify it.

![CE Automatic Shandong factory artificial rice make machinery processing line]()

No |

Name |

Brief introduction |

1 |

Raw material |

corn, rice, wheat, oat, barley, millet, sorghum etc as main ingredients |

2 |

Basic Recipe |

salt sugar powder, flavor material, cocoa powder and so on…. |

3 |

Processing flow |

Mixing system; Extrusion system; Drying system; Flavoring system;packSystem |

4 |

Equipment involved |

Mixer; Screw elevator; Double screw extruder; Air conveyor; Dryer; Flavoring system;Pack machinery |

5 |

Final products |

Variety shapes are available for ball, tube, stick, ring,

fruit loop, star, wheel and flower and heart shape cereal snacksby adjusting the mould in the extruder ;

|

6 |

machinery material |

Stainless steel 304 or as customer’s request |

![CE Automatic Shandong factory artificial rice make machinery processing line]()

Technical Parameter

| Model |

DZ65 Doule-screw Processing Line |

DZ85 Doule-screw Processing Line |

| Input VoLDage |

380V/ 50Hz |

380V/ 50Hz |

| Installed Capacity |

85kw |

105kw |

| Power Consumption |

65kw |

85kw |

| Output |

150-200kg/h |

400-500kg/h |

| Length |

22m |

28m |

Packaging & Shipping1. Testing machinery before package

2. Package:

The machinerys will be wrapped by plastic film or packed into wooden cases. Firstly,

anti-rust oil painted to the machinery, then wrapping film and air bubble pad then export

non-fumigation wooden casespackoutside.

Containers will be sent to our factory to load the machinerys and will be sealed before

being sent out to make sure the safety of our machinerys.

Or any other ones agreed between buyer and seller

Company InformationCompany profile

We are a LD supplier of food extruder and food in China.

Our factory, the chief member of the China Foodstuff andpack association,

has 20 years of experience in the extrusion food industry. With years' of research

anddevelopment, the extrusion technical has been widely used in many fields including puffed

snacks, pet food and fried snacks pellets, cheetos, kurkure,niknaks production machinery etc.

Our products consist of extrusion snack machinery, food extruder, breakfast cereals and corn

flakes machinery, Tortilla corn chips machinery, bugles machinery, twin screw extruder, cheetos,

kurkure,niknaks extruder, pet food machinerys and floating fish feed , dog chewing

food machinery, textured soya protein machinery, modified starch machinery, artificial rice machinery,

bread crumbs machinery, single screw extruder, potato chips machinery, instant noodle machinery

and biscuits machinery, instant flour machinery etc.

We can also provide special desity and customized products according to our clients’ special

requirements. We always take each client as " V I P ", and offer every client good service and

price. Our products have been sold to more than 1 0 0 countries and regions all over the world.

![CE Automatic Shandong factory artificial rice make machinery processing line]()

![CE Automatic Shandong factory artificial rice make machinery processing line]()

Our main processing lines

No |

Product Line |

1 |

Popcorn machinery |

2 |

Pet Food Processing Line |

3 |

Macaroni Processing Line |

4 |

Fried Pasta Processing Line |

5 |

3D Processing Line |

6 |

Modified Starch Processing Line |

7 |

Nutritional Rice Processing Line |

8 |

Soybean Protein Food Processing Line |

9 |

Automatic Instant Noodle Processing Line |

10 |

Extrusion Fried Pellet Snacks Processing Line |

11 |

Corn Flakes/ Breakfast Cereals Processing Line |

12 |

Extrusion Baked Puffed Snacks Processing Line |

Contact

Please feel free to contact us if you are interested in any of our products. We sincerely hope to cooperate with clients from all over the world.

Have a good day~