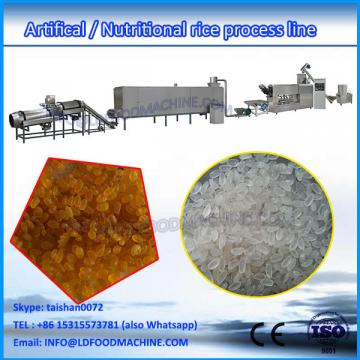

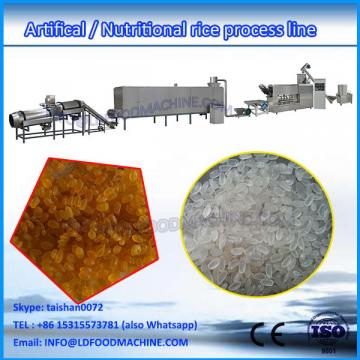

Extruded Nutrition Artificial Instant Rice Processing Line

Product DescriptionIntroduction:

There are two LLDes of extruder can be choosed in this processing line, DZ65-II or DZ85-II .Different extruder can produce different products and their output is also different .The processing line has high output and stealt performance.Besides ,its easy to operate.You can use corn powder,rice powder ,wheat flour ,millet or buckwheat as raw materials.The rice which is produced by the processing line is crystal ,brillant and nutritional.

Product Effects Artificial rice production of low cost, easy manufacture, good product quality, starch content low nutrient rich, smooth and beautiful product appearance, color is diverse, good bonding properties of the finished products, soft taste, not easy ageing can direct edible, but also for people according to the characteristics of the rice processing edible.

![Extruded Nutrition Artificial Instant Rice Processing Line]()

![Extruded Nutrition Artificial Instant Rice Processing Line]()

Technical Parameter

Parameters / Mode |

Double-screw process line

DZ65-II

|

Double-screw process line

DZ85-II

|

Input VoLDage |

380V/ 50Hz, customized |

380V/ 50Hz,

customized

|

Installed Capacity |

85kw |

105kw |

Power Consumption |

65kw |

85kw |

Output |

150-200KG/h |

300-400kg/h |

Length |

20m |

25m |

Production LineSchematic Flow:

Material---Mixing---Extruding&Shaping---Air convey---Roller drying---Air convey---Drying---Polishing

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting.

Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting

or replacing of materials.

2. Adopting speed- adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machinery, stable materials feeding

in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for

wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio,

whole-expanded and half expanded as different LLDe of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

After-Sales Service1. Guarantee for one year.

2. 24-hour technical support by or call.

3. User-friendly English manual for machinery using and maintaining.

4. Free technician training for large customers.

Packaging & Shipping

VCard

![Extruded Nutrition Artificial Instant Rice Processing Line]()

![Extruded Nutrition Artificial Instant Rice Processing Line]()