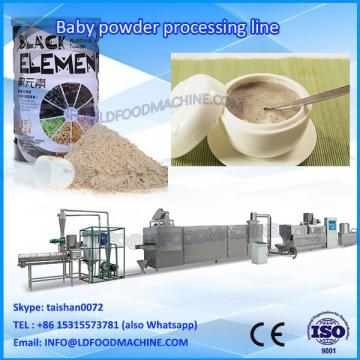

Nutritional Powder Processing Line

Product DescriptionIn extruder, the ingredients are cooked under intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife.Animal food is dried in a multi-pass dryer until its moisture content is low enough to make it shelf stable. Animal food may pass through a coating drum where animal fat and vitamins are applied onto animal food.

a. Raw Materials: adopts corn rice flour, soyLDean protein as raw materials

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 80-120kg/h, 150kg/h, 240kg/h, 500kg/h, 1ton---3ton/h

d. Flow chart:

Mixing system---Extrusion system---Drying system---Grinding system---Pack system

e. VoLDage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voLDage according to different countries

f. machinerys Materials: All the extruder machinery are made by stainless steel, this line is with reasonable desity and with high automation; the screws are made by alloy steel, with builting block system structure and self-cleaning function.

machinery Parametersmachinery Parameters:

| Model |

Installed Power |

Power Consumption |

Capacity/Output |

Dimension |

| LD56-II Twin Screw Extruder |

42.9kw |

30kw |

120-180kg/h |

3070x960x2050mm |

| LD65-III Twin Screw Extruder |

31.3kw |

22kw |

100-150kg/h |

2600x960x2000mm |

| LD70-III Twin Screw Extruder |

64.45kw |

40kw |

200-250kg/h |

3320x960x2100mm |

| LD75-III Twin Screw Extruder |

79.05kw |

50kw |

250-350kg/h |

4650x1100x2200mm |

| LD80-III Twin Screw Extruder |

97kw |

72kw |

350-500kg/h |

4800x1100x2300mm |

| LD85-II Twin Screw Extruder |

54.3kw |

40kw |

400-700kg/h |

4500x900x0mm |

| LD90-II Twin Screw Extruder |

89.7kw |

67.3kw |

500-800kg/h |

5200x1100x2200mm |

| LD100-I ITwin Screw Extruder |

161.3kw |

121kw |

800-1000kg/h |

5800x1200x2500mm

|

Brief Introduction of our company

Our factory has over 22 years experience of the industry development. We have well-experienced managers,outstanding engineers as well as well-trained technical workers. By constant technical exchange with well known firms of the same line in the worldand also by introduction of advanced techniques and experiences into our company,we have established a strong technical guarantee system.According to the clients' different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food and so on. Our technical assistance will help clients produce high quality products all the time. Depending on our rich experience and professional experts on the extruded food industry, we could offer the most suitable and complete program to assure that your investment will get biggest profit.

Pack & very

1.Packaging: daub coal oil on the surface to protect the machinery from moisture, Then cover with plastic film.Finally pack them with wooden case.

2.Customer's specialpackrequirement is available.

![Nutritional Powder Processing machinery]()

Customer Visit

Clients from around the worldcome to visit our company inLDect our machinerys as well as do the testing .

![Nutritional Powder Processing machinery]()

Customer Factory

This is our customer’s factory which we sold our machinerys to .Our products are exported to over 200 countries and regions in the worldand have won great prize.

Certificate

Our company has obtained many honors ,patent ,and famous certificates in our nation as well as the world.

Exhibition

![Nutritional Powder Processing machinery]()

With principle of reciproCity and mutual benefit, with better quality and more competitive price,we are honored to welcome you to visit us and to inquiry LDout us sincerely.

![Nutritional Powder Processing machinery]()