- 86-05331-85064683|

- Request a quote

See More

In recent years, with the rapid development of food industry, fried food has been widely involved in children's food, fast food, meat filling food, frozen food, microwave food and pasta products and many other fields. With the continuous improvement of food frying technology and the continuous expansion of production scale, the frying equipment is also developing towards industrialization, serialization and intellectualization. Among them, the typical continuous fryer has developed from the simple type in 1980s to the modern intelligent type; the breadth of frying is 250, 400, 600 and 800 m m, the length of frying is 2, 5, 4, 6 and 8 m, and the heating methods adopted are electric heating, gas heating or coal burning. Intermittent fryers are also developing in the direction of oil-saving, energy-saving and environmental protection, with the emergence of oil-water integrated structure fryers and so on.

Frier is the key equipment of food frying processing. According to the air pressure during frying, it can be divided into atmospheric pressure fryer and vacuum fryer. Atmospheric fryers are generally open and widely used. According to the way of frying, it can be divided into continuous fryer and intermittent fryer. According to the added liquids in food processing, it can be divided into traditional fryer and water filter fryer. In addition, there are special fryers specially designed for a particular kind of material.

Characteristics:

1) Continuous fryer can use salad oil, peanut oil, rapeseed oil and palm oil according to the needs of frying materials. It can be used for fried meat pies, rice cakes, potato cakes, various mixed cakes, French fries, potato chips, fish balls and meatballs.

2) The traditional continuous fryer adopts the device of external filtering and circulating oil circuit, which makes the oil heated by heater in the flow of uniform circulation in the main oil tank, so that the temperature of oil can rise uniformly and steadily. In addition, when the circulating oil passes through the double-layer (thick and fine) filter screen of the auxiliary tank, it clears the large and small particles residue in the oil, ensures the cleanliness of the oil, thus keeping the fried materials clean at any time.

3) The structure of traditional continuous fryer is concise and reasonable, and its function is advanced. Double mesh belt stepless speed regulation ensures not only the different frying time of frying, but also the smooth heating and transportation of frying at 2-3 cm below the oil layer. The cover can be lifted and lowered conveniently by using gantry frame and lifting mechanism, which is convenient for frying food.

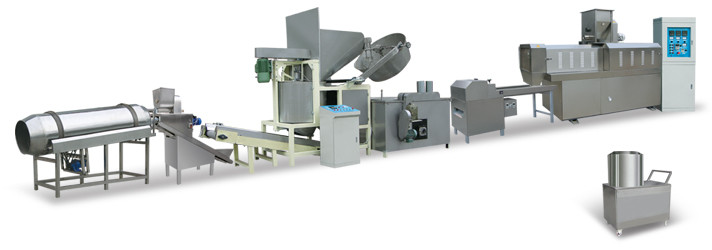

Fried Pellet Snacks Processing Line:

Working principle:Water filter fryer is designed based on the principle of different proportion of oil and water, incompatible with each other and automatic stratification. The tank is equipped with high temperature oil layer (heating oil layer), buffer oil layer (filtering oil layer) and water layer (sedimentation layer). The debris falling from the explosive material falls into the water layer through the buffer reservoir before carbonization in the high temperature reservoir, and is discharged regularly by the slag discharge outlet. The residue floating on the surface of hot oil is filtered out after it enters the filter tank driven by the hot oil circulating pump. In addition, because of the buffer layer, the one-time fuel consumption is twice as much as that of the same breadth fryer, but the actual fuel consumption of the material is only 70% of that of the same breadth fryer.

Structure:The structure of the water filter continuous fryer is basically the same as that of the standard continuous fryer. It only adds water layer to the tank, which is more complex. It is mainly used in the production line of large food processing enterprises to realize mass production. The structure, working principle and characteristics of a small intermittent water filter fryer are described in detail below.The lower part of the side wall of the oil tank is provided with an oil discharge outlet and a drainage outlet.

Processing Line:Working Principle:Before use, water is poured into the tank, the water level does not exceed the central position of the oil mark, and then into the oil. The different proportion of oil and water and their incompatibility make oil and water stratified. The heating tube is used to heat the upper oil, and the heat sink is used to block the heat transfer downward, which reduces the disturbance of the upper fried food and the lower oil layer when the frying oil turns over. The control panel is equipped with intelligent instruments, which can automatically control the oil temperature and keep it in a suitable range.

Characteristics of -type batch fryer:

The structure of central heating and oil-water mixing can increase heating speed, save energy and oil, and fry all kinds of food at the same time. In the process of frying, because of the proportion relationship between vegetable oil and animal oil, the animal oil leached from fried meat food naturally sinks into the lower layer of vegetable oil, so the working frying oil in the upper and middle layer is always kept pure. It can fry all kinds of food at the same time, without cross-flavor, effectively reduce the degree of oxidation of frying oil, and inhibit the increase of acid value.Residues can be removed in time to achieve self-cleaning, which is one of the reasons why the oil remains pure. Because of the automatic control of oil temperature and water temperature, the oxidation degree of frying oil is effectively reduced (i.e. the oil is not easy to paste), the structure of traditional frying equipment is completely changed, and the disadvantages of traditional frying pan are fundamentally overcome. The fried food not only has good color, fragrance, but also has clean and beautiful appearance, which improves the quality of products. It is widely used in hotels, hotels, fast food restaurants, hostels, troops, colleges and enterprise canteens, etc.

Working Principle and Structure of Oil-Sprinkled Frier:

Oil-sprinkled fryer is suitable for low-temperature fried food, such as chili oil. This kind of material needs lower oil temperature, and if the oil temperature is too high, it will fry paste. Therefore, it is not possible to use mesh belt type continuous fryer or water filter type fryer. At present, most of the materials such as pepper are fried artificially. There are some problems, such as low productivity, easy to fry paste, and workers are often choked by spicy fumes. Based on the characteristics of pepper and other materials, a specially designed oil-spraying fryer can be used.

Working Principle:

When the oil-spraying fryer works, First, the paver evenly spreads the fried food (such as cut chillies) on the screen. At the same time, the heated frying oil flows into the oil pipe from the oil tank under the action of the oil pump, and is sprayed onto the screen through the oil-spraying pipe. Because the screen rotates under the drive of the reducer, the fried food is processed by frying. The frying oil injected into the sieve is flowed into the oil receiving pan through the hole of the sieve, then filtered through the oil return pipe and the filter funnel, and then returned to the oil tank for recycling.

Characteristics:

1) The contact time between the frying oil and the food to be fried is short, so as to ensure that the food to be fried will not be fried.

2) When fried pepper and other materials, the fume is especially pungent and pungent, which is harmful to the respiratory system of processors. Therefore, there are smoke exhaust devices on the top of the screen and the top of the fuel tank, so as to ensure that the operator's body will not be harmed.

3) The oil temperature of the material after frying will decrease, but it can be recycled after returning to the tank for heating, saving oil and making full use of heat energy.

Fried food is one of the traditional foods in China. It is loved by people because of its crispness, delicious aroma and appetite promotion. However, the hazards of food processed by traditional frying methods, as well as the energy and energy consumption of fryers, have also attracted widespread attention. Therefore, the development and improvement of frying technology and fryer should focus on solving the above two problems.

1) Green frying should be advocated to reduce the production of acrylamide and other toxic substances in fried food. In terms of frying methods, vacuum frying technology is adopted as far as possible; in frying equipment, water filter fryer and vacuum fryer are mainly used. In the future, the research and development of vacuum frying technology and oil-water mixed frying technology should be further strengthened, as well as the improvement of related fryers and the research and design of new practical frying machines.

2) At present, most of the existing fryers are mainly in the form of electric heating,, the increasing tension in the use of electricity poses new challenges today; in addition, most of the oil after processing is naturally cooled, it needs to be reheated in the next processing, In the future, we should strengthen the improvement, design and development of gas-fired and coal-fired fryers. In the effective use of energy, frying machine design as far as possible to consider the installation of insulation devices, so that the hot oil after processing can be heat preservation, reduce energy loss.

See the news list>>