- 86-05331-85064683|

- Request a quote

See More

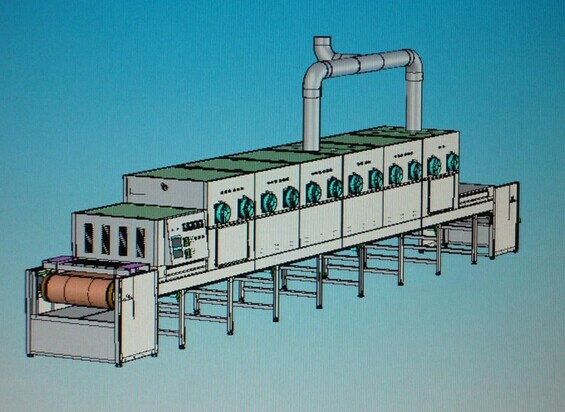

Microwave drying machine:

Electromagnetic radiation drying is to use the electromagnetic induction or infrared radiation effect of microwave to heat and dry materials. Different from other external heating drying methods, this drying method is a method of uniform heating from both outside and inside of the material. Therefore, this drying method has a short time, does not deteriorate or coke due to overheating, and its drying products are of good quality, especially the drying effect of heat-sensitive food is more satisfactory.

The microwave drying system is mainly composed of microwave generator, power supply, waveguide device, heater, cooling system, transmission system and control system.The microwave tubes used for heating and drying are mainly klystrons and magnetrons. Klystron is often used in high frequency or high power applications. Microwave generated by microwave tube is transmitted to heater through waveguide device. The heaters are mainly box type, plate type and waveguide type.

Usage of conti microwave drying machine:

Food microwave dryer is mainly used for paste food, powder food, granular food, agricultural products, and other products that need to be dried. Microwave dryer can be designed and manufactured according to different needs of different products.Heating Principle of Microwave Dryer:Microwave refers to electromagnetic waves with frequencies ranging from 300 MHz to 300 MHz. The water molecule in the heated medium material is a polar molecule. Under the fast changing high frequency electromagnetic field, its polar orientation will change with the change of external electric field, resulting in the movement of molecules and mutual friction effect. At this time, the field energy of microwave field can be transformed into heat energy in the medium, which makes the material temperature rise, and produces a series of physical and chemical processes, such as heating and expansion, to achieve the purpose of microwave heating and drying.

Because microwave energy of microwave drying equipment is controlled to work in metal drying chamber and waveguide, microwave leakage is less, radiation hazards and harmful gas emissions are not produced, waste heat and dust pollution are not produced, food is not polluted, microwave drying equipment is not polluted the environment.

See the news list>>

See the news list>>