- 86-05331-85064683|

- Request a quote

See More

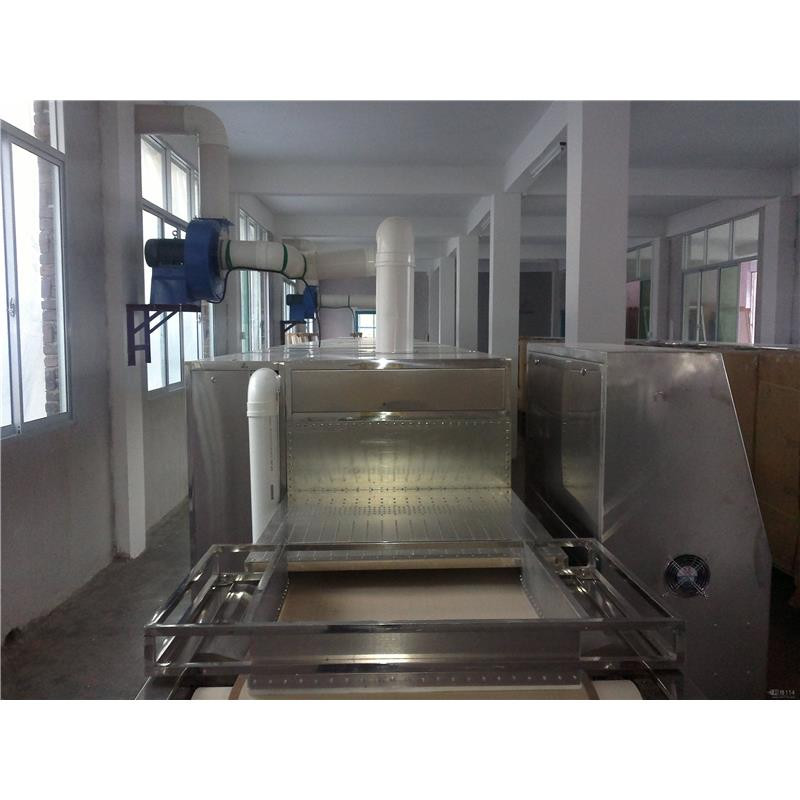

Using natural conditions to dry materials, including roasting, sun drying, wind blowing and other methods, clothing and food can be simply dried. With the development of the times, drying materials under natural conditions can not meet people's requirements. The emergence of microwave drying equipment and other drying equipment has greatly improved the drying efficiency and drying effect.

The microwave of microwave drying machine is a kind of electromagnetic wave with short wavelength, whose wavelength is between 1 m m and 1 m, and its corresponding frequency is from 300 GHz to 1 m.Between 300 MHz. In order to prevent the interference of microwave to radio communication, broadcasting and radar, there are four frequencies for microwave heating and microwave drying, which are L-band, frequency 890-940 MHz, wavelength 330 mm; S-band, frequency 2400-2500 MHz, wavelength 122 mm; C-band, frequency 5725-5875 MHz, wavelength 52 mm; K-band, frequency 2200-22250MHz, wavelength 8 mm. Only L and S segments are used in household microwave ovens.

Microwave oven drying machine is a kind of microwave drying equipment, which is obtained by the special movement of electrons in the magnetic field through DC or 50Hz alternating current on the electro-vacuum device or semiconductor device. This motion can be explained simply as follows: from the point of view of dielectric structure, one kind of molecule is called non-molecule dielectric, and the other kind is called molecule dielectric. Microwave drying equipment in general, they are arranged irregularly, if they are placed in an alternating electric field, the orientation of the neutral molecules of these media also changes with the electric field.

Change by change, which is called change. The stronger the applied electric field is, the stronger the microwave drying equipment will be. The faster the applied electric field changes, the faster the microwave drying equipment will change. The more intense the thermal movement of molecules and the friction between adjacent molecules will be. In this process, the conversion of electromagnetic energy to thermal energy is completed. When the heated material is placed in the microwave field, the molecule of microwave drying equipment swings and rubs back and forth with the microwave frequency of billions of times per second. The heat generated by microwave drying equipment is enough to make the material hot-dry in a very short time.

Anti-mildew, sterilization and preservation of microwave drying equipment:

Microwave drying equipment has thermal and biological effects. Microwave drying equipment can sterilize and prevent mildew at lower temperature. Because of its fast drying speed and short drying time, it can preserve the activity of materials and vitamins, original color and nutritional ingredients in food to a great extent.Advanced Technology:As long as microwave power is controlled, microwave drying equipment can achieve immediate drying and termination. Application of man-machine interface and PLC can be used for programmable automatic control of drying process and drying process specification.Safety and harmlessness:Because microwave energy of microwave drying equipment is controlled to work in metal drying chamber and waveguide, microwave leakage is less, radiation hazards and harmful gas emissions are not produced, waste heat and dust pollution are not produced, food is not polluted, microwave drying equipment is not polluted the environment.

See the news list>>