- 86-05331-85064683|

- Request a quote

See More

The towel socks produced by Shangshang No. 5 Factory used to be packed in plastic bags by hand, which was slow and inefficient. Sometimes, because the plastic bag machine mouth is difficult to separate, it causes wrinkling phenomenon, which not only affects the speed of bagging, but also affects the appearance of packaging. The technical and leather team of the factory learned from the experience of the brothers'factory. It took only about half a year to make an automatic plastic bag machine for towel socks in May 1978. Its main feature is to use simple roll plastic film socks, sealed by the electric heater into bags and cut off plastic film, complete the packaging process.

Microwave drying machinery and equipment

In the trolley workshop of knitting mill, because of the contact of pawls and ratchets on the trolley reel rack, the noise of the whole trolley group is very large. In order to improve the working conditions of the workers, the metalworking group of Shanghai Knitting Underwear Factory and the workshop security workers jointly studied, boldly innovated and repeatedly tested, and finally succeeded in the trial-production of "trolley noise-free coiling mechanism". In order to get rid of ratchets and pawls which produce noise sources, they designed a split overrunning clutch with shifting fork to replace the ratchet mechanism according to the principle of overrunning clutch.

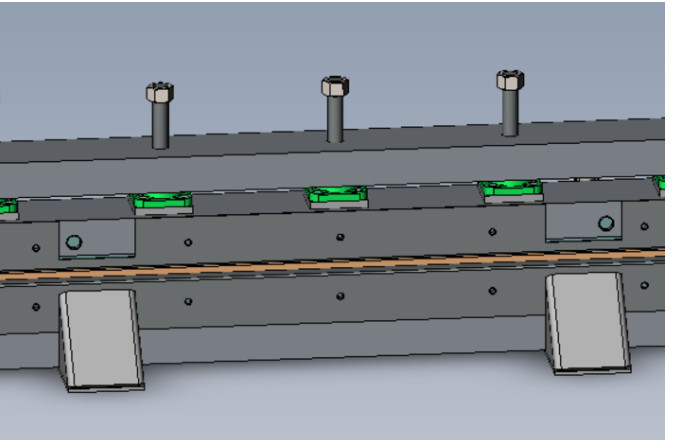

The mechanism is composed of moving coil, fixed coil, handwheel, cross shaft, roller, spring and other components. The moving coil is connected with the trolley connecting rod, and the fixing ring is fixed with the rolling rack. When the connecting rod moves under _L, it drives the moving coil to swing up and down. When it turns clockwise, the moving coil, the roller and the cross axle are wedged together under the action of the spring. The cross axle rotates accordingly, and the roller connected with the cross axle is rolled.

When the moving coil rotates counter-clockwise, the spring does not work, and the fixed coil is wedged with the roller and the cross axis, so that the cross axis can not be reversed, thus ensuring the tension of the cloth roll. In this continuous movement, the roll cloth rolls tightly into cloth. When it is necessary to drop cloth, turn the handwheel so that the positioning column is pushed into the "loose" hole. At this time, four forks on the handwheel push the roller away, so that the moving ring and the fixed ring are loosened with the cross shaft, so that the roll can be reversed freely. After the cloth is laid, a new coil roller is installed, and the handwheel is rotated again, so that the positioning column is jacked into the "tight hole" and the second coil is started. The mechanism works well, basically eliminating noise, making simple, low cost and easy maintenance.

See the news list>>