Save energy stainless steel microwave garlic slices dryer and sterilization machine, often colloquially shortened to microwave, is a kitchen appliance that heats food by bombarding it with electromagnetic radiation in the Save energy stainless steel microwave garlic slices dryer and sterilization machine spectrum causing polarized molecules in the food to rotate and build up thermal energy in a process known as dielectric heating. Save energy stainless steel microwave garlic slices dryer and sterilization machine heat foods quickly and efficiently because excitation is fairly uniform in the outer 25–38 mm of a dense (high water content) food item; food is more evenly heated throughout (except in thick, dense objects) than generally occurs in other cooking techniques. The microwave dryer can Sterilize the food during the drying process by heat and the influence on the protein, RNA, DNA, cell membrane and so on.

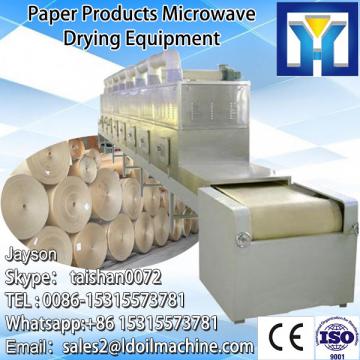

Save energy stainless steel microwave garlic slices dryer and sterilization machine

Principle of Microwave Drying

Microwave is a sort of electromagnetic wave which frequency is 300MHz to 300GHz .The water molecule in medium materials is polar molecule,under the effect of the rapid change of electromagnetic field,its polarity orientation will alter with the changes of the external electric field with the high-speed,causing the movement and friction of molecule.so that the microwave field energy can be converted to heat energy in medium to rise the temperature of materials.accomplishing heating ,puffing and a series of physical and chemical processes ,and so ,microwave heating is achieved.

Features of Design

Heating speed fast

Microwave directly on the internal and external tea simultaneous heating, do not need to preheat, boot can processing. While the traditional processing, there must be a preheated process.

Heating unifrom

Microwave drying is shot by magnetic control of electromagnetic wave produced even ground illuminate to tea, while heating, no inside and outside the focal leaves, coke, elastic, etc., and the edge of the traditional method is through the heat conduction rollers to tea again and heat is not uniform, appropriate produce the endogenous, in the familiar dry wet. A burning smell, coke, clastic produce, serious leaf tea quality effect.

Green equipment, energy efficient.

Microwave is a direct effect on the material, without intermediate conversion to other sectors and therefore no additional heat loss, air and corresponding container furnace will not heat, so the high thermal efficiency, the production environment is also significantly improved, with the far-infrared heating phase.You can save more than 30%.

Reference of Picture

Packing and Shipping

1. Delivery Term:FOB/CFR/CIF

2. Delivery time:20 work days after having received payment

3. Package:wooden cases(fully meets with export package requirements)

4. Payment Terms:50% deposit by T/T,balance 50% paid by T/T before shipment.

5.Transportion:By vessel

NOTE:We can specially design the machine according to your production's features.

LD

Save energy stainless steel microwave garlic slices dryer and sterilization machine

Shandong Leader Machinery Co.,ltd. Save energy stainless steel microwave garlic slices dryer and sterilization machine are widely used in the peanuts,wheat,corn,filbert and dried fruit etc;and for puffing of leisure food,pachyrhizus chips,potato chips,dried shrimps,fish maw and so on.Compared with the traditional production methods,microwave baking foods are crispy and delicious,puffed full of particles,natural color, beautiful appearance,and has insecticidal sterilization effect.

AAA1

China supplier microwave drying and roasting equipment Advantage

1,continue produce

2,keep original color and nutration

3,easy to control

4,save energy

5, save labours

6 ,improve the quality of products, increase income.

AAA2

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: sales9@ldfoodmachine.com