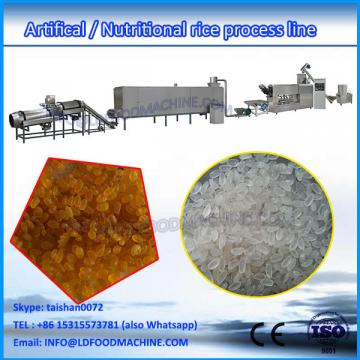

Product Description2016 Various Nutrition Rice Flourpackmachinery puffed rice make machinery

Technical Parameter

Parameters / Mode |

Double-screw process line

DZ65-II

|

Double-screw process line

DZ85-II

|

Input VoLDage |

380V/ 50Hz, customized |

380V/ 50Hz,

customized

|

Installed Capacity |

85kw |

105kw |

Power Consumption |

65kw |

85kw |

Output |

150-200KG/h |

300-400kg/h |

Length |

20m |

25m |

1. Raw materials adopts broken rice rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.

2. Products: This line can be used to produce artificial rice, LDstituted rice.

3. Capacity: 100kg/h, 200kg/h, 300kg/h,3000tons/year, 5000tons/year

4. Flow chart: Material--Mixing system--Extruing&shaping---Air convey---Drying--Polishing

5. machinerys materials: All the machinerys are made by stainless steel, this line is with reasonable desity and with high automation; the screws are made by alloy steel, with builting block system structure and self-cleaning function.

Nutrition rice production line:

![2016 Various Nutrition Rice Flourpackmachinery puffed rice make machinery]()

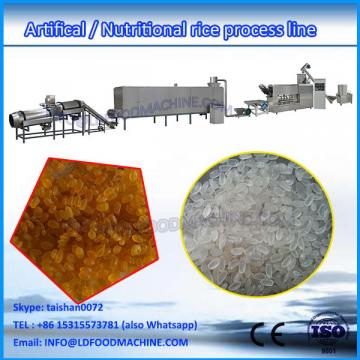

Product Feature

1) Simple structure in linear LLDe ,easy in installation and maintation.

2) Adopting advanced worldfamous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double screws could pressing into differents shapes and size artificial rice .

4) Running in a high automatization and inlectualization,no pollution

5) Mixer-extruder- dryer-cooling

Packaging & Shipping

![2016 Various Nutrition Rice Flourpackmachinery puffed rice make machinery]()

Company InformationOur Company

Our customer

Our Services

Our main processing lines

No |

Product Line |

1 |

Popcorn machinery |

2 |

Pet Food Processing Line |

3 |

Macaroni Processing Line |

4 |

Fried Pasta Processing Line |

5 |

3D Processing Line |

6 |

Modified Starch Processing Line |

7 |

Nutritional Rice Processing Line |

8 |

Soybean Protein Food Processing Line |

9 |

Automatic Instant Noodle Processing Line |

10 |

Extrusion Fried Pellet Snacks Processing Line |

11 |

Corn Flakes/ Breakfast Cereals Processing Line |

12 |

Extrusion Baked Puffed Snacks Processing Line |

contact

![2016 Various Nutrition Rice Flourpackmachinery puffed rice make machinery]()