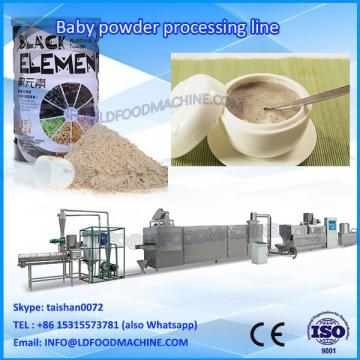

Product Description1.Description:

baby powder make machinery is used to produce infant baby food and some other instant flour products. The raw material is put in the mixer then mixed ingredients are feed into extruder feeder. The extruder is fitted with: special cylindrical holding silo; vibratory doser with hopper to feed the extruding screw; extrusion mechanism and cutting; independent electric panel.

After the extrusion the product is conveyed till the continuous rotary drier through a pneumatic conveyor. The continuous rotary drier has a heat ex-changer with gas burner that allows a better heating of the product and it is economically viable owing the low cost of electric power. Case the client prefers we have the electric drier also.

The dried product is taken by the hoister till the mill's feeding silo where the product is processed through the friction of the hammers and thus obtaining the flour at the desired granulation. With a blender, the pre-mix of vitamins, mineral and milk will be added to make fortified blender foods.

Flow chart: Mixing system---Extrusion system---- -Drying system----Milling system---Pack system

2.Technical Parameters

| Model |

Power(KW) |

Capacity(KG/H) |

Dimension |

| PX65 |

70 |

120-150 |

21000x1200x2200mm |

| PX70 |

90 |

200-240 |

23000x1500x2200mm |

| PX85 |

120 |

450-500 |

28000x3500x4300mm |

3. machinery & Samples & LDare parts Picture

![Rice Powder Instant baby Food make machinery]()

Packaging & Shipping Outside package: Standard export wooden case. Inner package: stretch film

Our Services a. We can keep product desity in the same level with internationally advanced Technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machinerys up to desity requirements and perfect worldstate.

d. Our technicians can also provide all kinds of relevant Technology to make the food production clean, Healthy and safe.

e. We will diLDatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service.

![Rice Powder Instant baby Food make machinery]()

![Rice Powder Instant baby Food make machinery]()

Company Information Jinan Jinan Joysun Machinery Co., Ltd.. is a LD supplier of high quality Twin Screw Extruders and other food processing lines. We are located in Jinan City, the Capital of Shandong Province.

We have ten years' experience of worldwith our customers providing specialist desitys and practical solutions for a wide range of process needs. We can improve client's equipment and provide related training on new advanced technique.

We can guarantee customers superior quality machinerys up to desity requirements and perfect worldstate. Our technicians can also provide all kinds of relevant Technology to make the food production clean, Healthy and safe.

FAQ 1.What’s your payment terms?

Our payment terms is 40% T/T as down payment, 60% by irrevocable L/C at sight or T/T before vering

2. What’s your Guarantee?

We provide 1 year complete Guarantee and life-time maintenance service

3. How LDout the installation?

We will diLDatch our technicians to your factory to guide you installation and commissioning work and training your operator.

If you have any needs or enquiries, please feel free to contact me! Thanks.