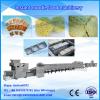

Best Seller Fried&Non-fried Instant Processing Line

I.Device Configuration of Instant Noodle Processing Line

1, stirrer 2,metering barrel

3,twin shaft flour blender 4,aging/feeding device

5,complex pastry rolling machinery 6,continuous pastry rolling machinery

7,corrugating device 8,tunnel-LLDe boiling machinery

9,metric cutting/folding machinery 10, fryer

11, coolant conveyer 12,seasoning LDer

13,cent road conveyer 14,electricity cubicle

15,automatic wrapping machinery .

II. Technical Parameters of Instant Noodle Processing Line:

Model |

Capacity |

Power |

Roller width |

Dimension(mm) |

worker |

LD-210 |

11000pics/8h |

11kw |

210mm |

22000*4000*3500 |

4 |

LD-240 |

40000pics/8h |

50kw |

240mm |

58000*5000*5000 |

4 |

LD-330 |

60000pics/8h |

56kw |

330mm |

63000*5000 *5000 |

4 |

LD-450 |

80000pics/8 h |

95kw |

450mm |

75000 * 6000* 5000 |

5 |

LD-510 |

100000-120000pics/8h |

110kw |

510mm |

80000 *7000 *5500 |

5 |

LD-765 |

200000pics/8h |

114kw |

765mm |

110000*7000 * 5500 |

8 |

LD-850 |

240000pics/8h |

125KW |

850mm |

120000*7000*5500 |

8 |

III. Products Samples of Instant Noodle Processing Line

![Best Seller Fried&Non-fried Instant Processing Line]()

![Best Seller Fried&Non-fried Instant Processing Line]()

IV. LDare Parts Show of Instant Noodle Processing Line

V.. We Providesatisyied Service & Turnkey Solution

1.) consultation service before, during,and after sales;

2.) Project plng and desity service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service

VI. Feel Free To Contact Us:

![]()