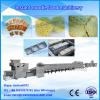

CE Approved Fried Instant Noodle Production Line

1. salt Water Mixer:water mixed with additive such as salt,altali. 2. Brine metering device:measuring the water demand for every pot flour so as to control quantitatively the salt water volume from salt water mixer into dough mixer.

3. Dough mixer:flour and water combined and mixed full.

4. Aging machinery:dough aging, improve the elastiCity of the flour

5. Pressing machinery:pressing and cutting

6. Steaming machinery:steaming the formed

7. Cutting& Dividing machinery: cutting, folding, dividing,, forming the dough pieces and entering boxes, it can form square or circular dough pieces from different molds.

8. Frying machinery: dehydrated by frying, fixing the shape of dough pieces, make dough crisp to taste good

9.. Cooling machinery: lower the temperature of dough pieces to meet the demand of Pack.

10 Conveyor: conveying finished instant to eachpackline.

11 Pack machinery: choosing sauce packagepackmachinery as customers’ request, powder packmachinery, vegetable bagpackmachinery, pillow LLDepackmachinery(instant in bags),captightener(instant in bowls), shrinkpackmachinery(instant in bowls),folding and sealing machinery and so on.

Pack machinery is optional, excluding standard quotation, choosing as requirement details.

Technical Parameter

Model |

Capacity ( k pcs/8 hour) |

Dimension (m) |

Power |

Roller specification

|

Operator |

Steam comsumption kg/H |

LD-(1~3)W |

20000-30000 |

48*6*6 |

36kw |

210mm |

4 persons |

800~1000 |

LD-(4~5)W |

40000-50000 |

56*6*6 |

48kw |

320mm |

4~5 persons |

1000~1200 |

LD-(6~8)W |

60000-80000 |

68*6*6 |

60kw |

420mm |

5 persons |

1200~1400 |

LD-(9~12)W |

90000-120000 |

74*6*6 |

78kw |

520mm |

5~6 persons |

1400~1600 |

LD-(13~16)W |

130000-160000 |

78*8*6 |

kw |

630mm |

6 persons |

1600~1800 |

LD-(17~20)W |

170000- 200000 |

82*8*6 |

92kw |

735mm |

7 persons |

1800~2000 |

LD-(21~24)W |

210000-240000 |

*8*6 |

100kw |

820mm |

7~8 persons |

2000~2500 |

LD-(25~30)W |

250000-300000 |

95*8*6 |

112kw |

1000mm |

8 persons |

2500~3500 |